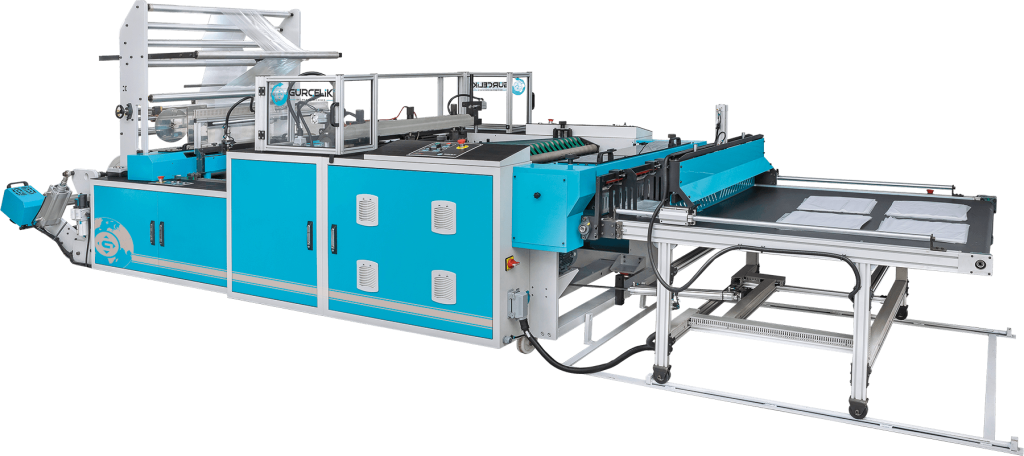

Technicial Specifications

Descriptions

Bag Types

Photos

Videos

Catalog

Technicial Specifications

Descriptions

- Servo motor and inverter system.

- Control screen (Temperature, production quantity, machine speed, etc. can be monitored).

- Automatic tilting jaw.

- Bag size can be changed.

- Synchronous roller.

- Rotating silicone on the lower jaw.

- Printed and unprinted bags are produced with photocell.

- Machine stops automatically when the photocell does not detect the printing and when the bobbin runs out; error message is seen on the operator panel.

- Bobbin lifting group provides more practical loading of bobbins with its locking wheel.

- The brake system is automatically adjusted according to the loaded kilograms.

- Standard machine includes taping device.

- Pneumatic ballerina system with motor, reducer and inverter.

- Belt motor speed is adjusted by inverter.

- Optionally, hole drilling and ultrasonic welding unit, additional welding and envelope device are provided.

- Side sealing is proceeded on the standard machine.

- Optionally, bottom seal welding application can be provided.

- The standard machine can proceed OPP, PP, CPP, high density (HDPE), low density (LDPE), bio material and second quality recycling.

- A retarded belt system is used on the machine.

Bag Types

Photos

Videos

Catalog