Technicial Specifications

Descriptions

Bag Types

Photos

Videos

Catalog

Technicial Specifications

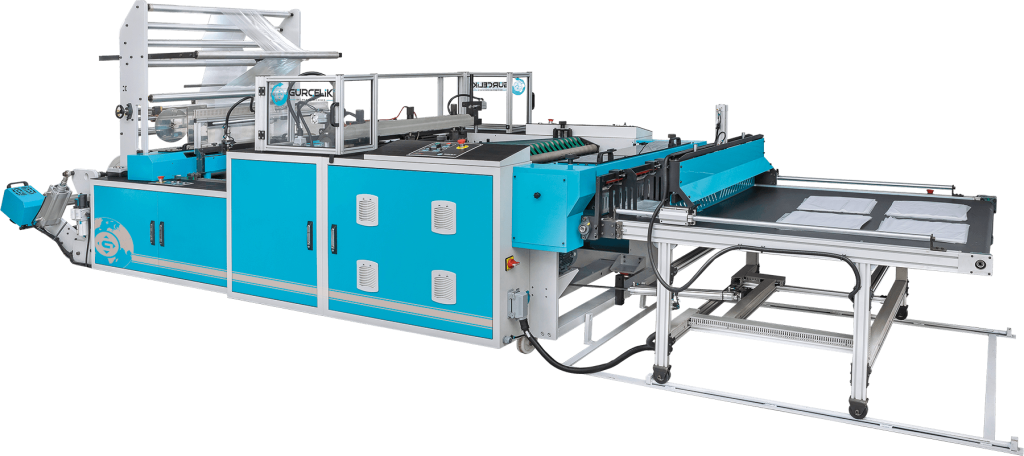

Descriptions

- Servo motor and inverter system

- Control screen (Temperature, production number, machine speed, etc. can be monitored)

- Automatically opening jaw

- Bag size can be changed.

- Synchronous roller

- Rotating silicone on the lower jaw

- With the photocell, printed and unprinted bags are produced.

- When the photocell does not see the printing, the machine automatically stops when the roll is finished; error message is given on the operator panel.

- Bobbin lifting group provides more practical loading of bobbins with its locking wheel.

- The brake system is adjusted automatically according to the weight loaded.

- The standard machine has a taping apparatus.

- Motorized, geared, inverter and pneumatic ballerina system,

- Belt motor speed is adjusted by inverter.

- Optional hole drilling and ultrasonic welding unit, additional welding and envelope apparatus are added

- Side cutting is done in the standard machine. Optionally, bottom seam welding application can be added.

- The standard machine can cut OPP, PP, CPP High density (HDPE), Low density (LDPE), Bio material and second quality recycling.

- Deceleration belt system

- Belt motor speed is adjusted by inverter.

Bag Types

Photos

Videos

Catalog