Technicial Specifications

Descriptions

Bag Types

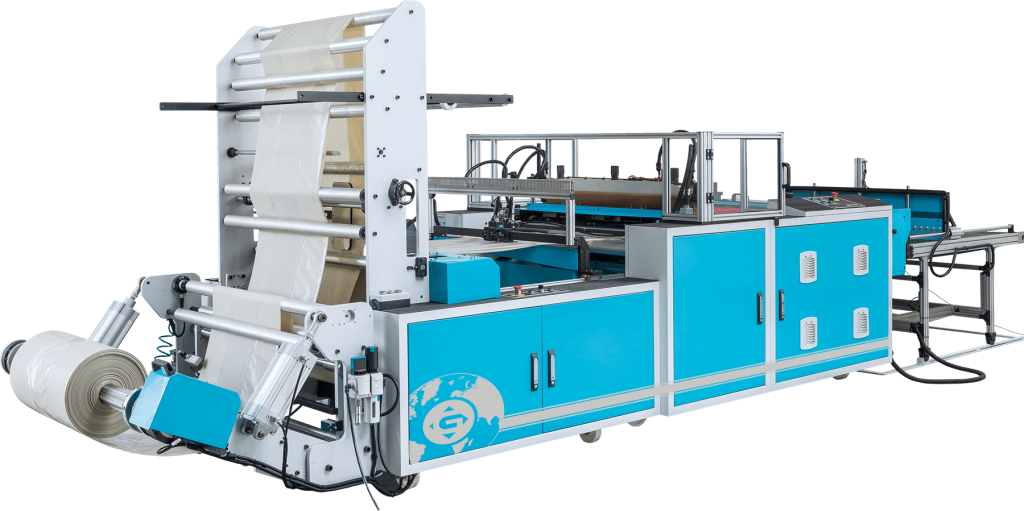

Photos

Videos

Catalog

Technicial Specifications

Descriptions

- Servo motor and invertor system.

- Easy to operate with the buttons for temperature, production quantity, machine speed

- etc. on the control screen.

- Bag size, speed and position of robot are automatically adjusted according to the bag

- size on the machine. All data can be monitored on the screen.

- Bobbin unwinding is proceeded with magnetic brake and loadcell according to kilogram.

- Product out system runs with sensor. Thus, the machine stops automatically when the film on the bobbin is finished.

- Bobbin lifting group enables more practical loading of bobbins with its locking wheel.

- Motor-driven edge control system is used on the machine

- Pneumatic ballerina system with reductor and invertor is used on the machine.

- Belt motor speed is adjusted by inverter.

- Standart machine has taping and cold slitting units.

- Synchronous roller and lower jaw are used as rotating silicone on the machine. In

- addition, bottom seal jaw system, double bobbin attachment system, double welding

- (ability to make T-Shirt bag) are available.

- Optionally, hole drilling and ultrasonic welding unit, additional welding and envelope

- device can be provided.

- Printed bags are cut precisely with the photocell system.

- Automatic tilting jaw system with pneumatic equipment enables use for the operator.

- The cut products are stacked on the conveyor at the release section of the machine

- and transported to the operator.

- Having capacity to work with OPP, PP, CPP, high density polyethylene (HDPE), low

- density polyethylene (LDPE), second quality recycling and bio materials

- on the standard machine.

Bag Types

Photos

Videos

Catalog