Technicial Specifications

Descriptions

Bag Types

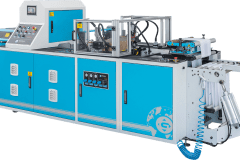

Photos

Videos

Catalog

Technicial Specifications

Descriptions

- Servo motor and invertor system

- Touch control screen (Temperature, production number, machine speed, etc. can be monitored)

- Automatically opening jaw

- Bag size can be changed from the operator panel. Speed and position of the robot can be adjusted in accordance with bag lenght

- Full automatic hydraulic press unit controlled by screen and PLC

- There is one photocell. Capacity to produce printed bags and none-printed bags with photocell

- With the photocell sensor, the printed bags are brought to the cutting position automatically. When the print slip or unprinted product arrives, the machine automatically stops and alarms and appears on the operator panel.

- Having capacity to work with HDPE, LDPE and second quality recycled materials

- All bags are stacked on hot and cold pins located 10 cm inside from the open side of the bag

- Edge control system

- With the rock unit welding lines are not superimposed on the other bag’s welding line

- With the product finished sensor, alarm is given when the product is finished, the alarm appears on the operator panel.

- The cut products are stacked on the conveyor belt

- Wastes are carried out of the machine by the fire conveyor

- Optional equipment can be added

Bag Types

Photos

Videos

Catalog